KATO STI Gages

Precision that ensures Accuracy.

Precision that ensures Accuracy.

KATO CoilThread STI (Screw Thread Insert) Thread Plug Gages are designed to check the accuracy of the internal thread of an STI tapped hole. Gaging the tapped hole prior to installation of the insert is critical to ensure the accuracy of the finished thread. If the tapped hole gauges correctly, the finished thread will also be accurate once the insert is properly installed and seated.

It is not necessary to gage the installed insert. Gaging of the tapped thread is specified because a standard gage may not freely enter an installed insert. The insert will seat itself once a bolt or screw is installed and tightened (Ref. NASM33537). In fact, it is not possible to gage a locking type insert because of the locking coil.

Recommended for production use since their greater tolerance allows for more wear.

Pitch diameters at or very close to the basic size and are to be used as master gages.

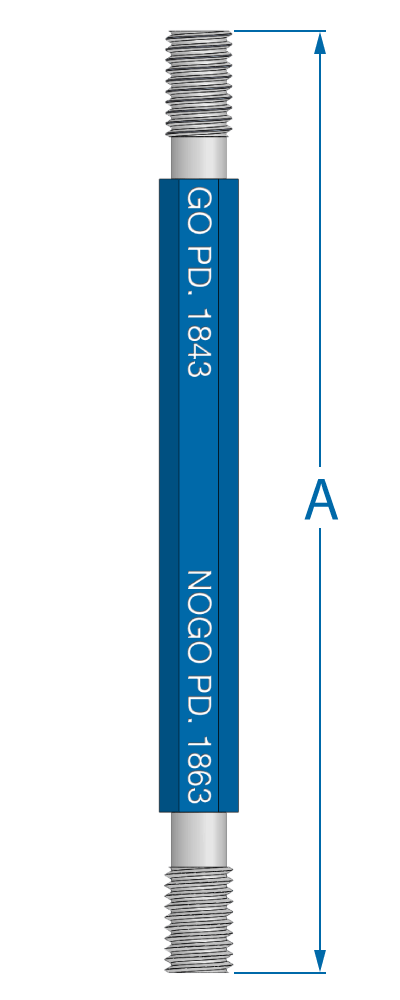

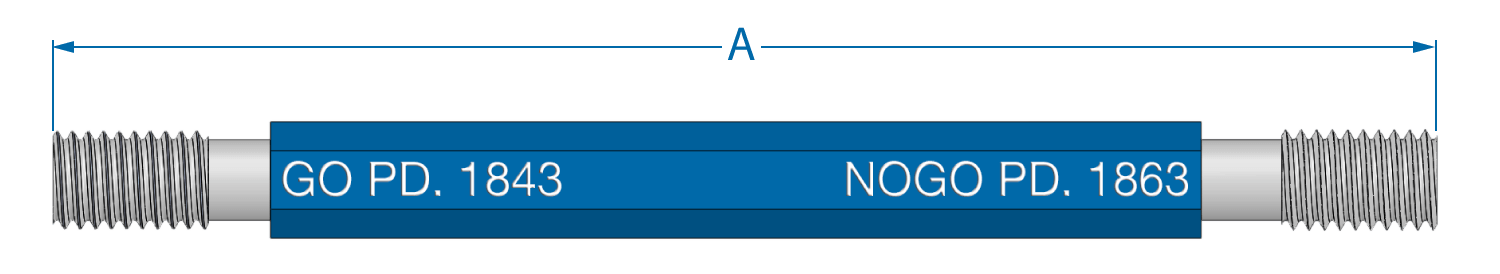

KATO CoilThread Gages include a "GO" and "HI" (NO GO) member. The Working Gage "GO" member has a 0.0002 wear allowance on the pitch diameter. The "GO" member checks the basic pitch diameter, major diameter minimum and lead. The "HI" member checks the maximum pitch diameter. The minor diameter must be checked separately with a graduated pin set.

For fast and accurate part numbers and technical information on specific inserts try out the KATO Product Wizard.

Example of a KATO CoilThread Gage part number:

CG C - 02 X - 3B

1 2 3 4 5

| 1 Tool Type |

2 Thread Designation |

3 Size Designation |

4 Style / Type |

5 Class of Fit |

|---|---|---|---|---|

| CG - CoilThread Gage (STI) | C- Unified Coarse F - Unified Fine M - Metric |

Chart Below | X - Working W - References |

See Notes at the bottom |

| Thread Size |

Working Gages | Reference Gages | ||

|---|---|---|---|---|

| 3B | 2B | 3B | 2B | |

| Unified Coarse | ||||

| 1-64 | CGC-01X-3B | CGC-01X-2B | CGC-01W-3B | CGC-01W-2B |

| 2-56 | CGC-02X-3B | CGC-02X-2B | CGC-02W-3B | CGC-02W-2B |

| 3-48 | CGC-03X-3B | CGC-03X-2B | CGC-03W-3B | CGC-03W-2B |

| 4-40 | CGC-04X-3B | CGC-04X-2B | CGC-04W-3B | CGC-04W-2B |

| 5-40 | CGC-05X-3B | CGC-05X-2B | CGC-05W-3B | CGC-05W-2B |

| 6-32 | CGC-06X-3B | CGC-06X-2B | CGC-06W-3B | CGC-06W-2B |

| 8-32 | CGC-2X-3B | CGC-2X-2B | CGC-2W-3B | CGC-2W-2B |

| 10-24 | CGC-3X-3B | CGC-3X-2B | CGC-3W-3B | CGC-3W-2B |

| 12-24 | CGC-1X-3B | CGC-1X-2B | CGC-1W-3B | CGC-1W-2B |

| 1/4-20 | CGC-4X-3B | CGC-4X-2B | CGC-4W-3B | CGC-4W-2B |

| 5/16-18 | CGC-5X-3B | CGC-5X-2B | CGC-5W-3B | CGC-5W-2B |

| 3/8-16 | CGC-6X-3B | CGC-6X-2B | CGC-6W-3B | CGC-6W-2B |

| 7/16-14 | CGC-7X-3B | CGC-7X-2B | CGC-7W-3B | CGC-7W-2B |

| 1/2-13 | CGC-8X-3B | CGC-8X-2B | CGC-8W-3B | CGC-8W-2B |

| 9/16-12 | CGC-9X-3B | CGC-9X-2B | CGC-9W-3B | CGC-9W-2B |

| 5/8-11 | CGC-10X-3B | CGC-10X-2B | CGC-10W-3B | CGC-10W-2B |

| 3/4-10 | CGC-12X-3B | CGC-12X-2B | CGC-12W-3B | CGC-12W-2B |

| 7/8-9 | CGC-14X-3B | CGC-14X-2B | CGC-14W-3B | CGC-14W-2B |

| 1-8 | CGC-16X-3B | CGC-16X-2B | CGC-16W-3B | CGC-16W-2B |

| 1-1/8-7 | CGC-18X-3B | CGC-18X-2B | CGC-18W-3B | CGC-18W-2B |

| 1-1/4-7 | CGC-20X-3B | CGC-20X-2B | CGC-20W-3B | CGC-20W-2B |

| 1-3/8-6 | CGC-22X-3B | CGC-22X-2B | CGC-22W-3B | CGC-22W-2B |

| 1-1/2-6 | CGC-24X-3B | CGC-24X-2B | CGC-24W-3B | CGC-24W-2B |

| Unified Fine | ||||

| 0-80 | CGF-00X-3B | CGF-00X-2B | CGF-00W-3B | CGF-00W-2B |

| 3-56 | CGF-03X-3B | CGF-03X-2B | CGF-03W-3B | CGF-03W-2B |

| 4-48 | CGF-04X-3B | CGF-04X-2B | CGF-04W-3B | CGF-04W-2B |

| 6-40 | CGF-06X-3B | CGF-06X-2B | CGF-06W-3B | CGF-06W-2B |

| 8-36 | CGF-2X-3B | CGF-2X-2B | CGF-2W-3B | CGF-2W-2B |

| 10-32 | CGF-3X-3B | CGF-3X-2B | CGF-3W-3B | CGF-3W-2B |

| 1/4-28 | CGF-4X-3B | CGF-4X-2B | CGF-4W-3B | CGF-4W-2B |

| 5/16-24 | CGF-5X-3B | CGF-5X-2B | CGF-5W-3B | CGF-5W-2B |

| 3/8-24 | CGF-6X-3B | CGF-6X-2B | CGF-6W-3B | CGF-6W-2B |

| 7/16-20 | CGF-7X-3B | CGF-7X-2B | CGF-7W-3B | CGF-7W-2B |

| 1/2-20 | CGF-8X-3B | CGF-8X-2B | CGF-8W-3B | CGF-8W-2B |

| 9/16-18 | CGF-9X-3B | CGF-9X-2B | CGF-9W-3B | CGF-9W-2B |

| 5/8-18 | CGF-10X-3B | CGF-10X-2B | CGF-10W-3B | CGF-10W-2B |

| 3/4-16 | CGF-12X-3B | CGF-12X-2B | CGF-12W-3B | CGF-12W-2B |

| 7/8-14 | CGF-14X-3B | CGF-14X-2B | CGF-14W-3B | CGF-14W-2B |

| 1-12 | CGF-161X-3B | CGF-161X-2B | CGF-161W-3B | CGF-161W-2B |

| 1-14 | CGF-16X-3B | CGF-16X-2B | CGF-16W-3B | CGF-16W-2B |

| 1-1/8-12 | CGF-18X-3B | CGF-18X-2B | CGF-18W-3B | CGF-18W-2B |

| 1-1/4-12 | CGF-20X-3B | CGF-20X-2B | CGF-20W-3B | CGF-20W-2B |

| 1-3/8-12 | CGF-22X-3B | CGF-22X-2B | CGF-22W-3B | CGF-22W-2B |

| 1-1/2-12 | CGF-24X-3B | CGF-24X-2B | CGF-24W-3B | CGF-24W-2B |

| Thread Size |

Working Gages | |

|---|---|---|

| 4H | 5H | |

| Metric Coarse | ||

| M2X0.4 | CGM-2X.4-4H | CGM-2X.4-5H |

| M2.2X.45 | CGM-2.2X.45-4H | CGM-2.2X.45-5H |

| M2.5X.45 | CGM-2.5X.45-4H | CGM-2.5X.45-5H |

| M3X.5 | CGM-3X.5-4H | CGM-3X.5-5H |

| M3.5X.6 | CGM-3.5X.6-4H | CGM-3.5X.6-5H |

| M4X.7 | CGM-4X.7-4H | CGM-4X.7-5H |

| M5X.8 | CGM-5X.8-4H | CGM-5X.8-5H |

| M6X1 | CGM-6X1-4H | CGM-6X1-5H |

| M7X1 | CGM-7X1-4H | CGM-7X1-5H |

| M8X1.25 | CGM-8X1.25-4H | CGM-8X1.25-5H |

| M10X1.5 | CGM-10X1.5-4H | CGM-10X1.5-5H |

| M12X1.75 | CGM-12X1.75-4H | CGM-12X1.75-5H |

| M14X2 | CGM-14X2-4H | CGM-14X2-5H |

| M16X2 | CGM-16X2-4H | CGM-16X2-5H |

| M18X2.5 | CGM-18X2.5-4H | CGM-18X2.5-5H |

| M20X2.5 | CGM-20X2.5-4H | CGM-20X2.5-5H |

| M22X2.5 | CGM-22X2.5-4H | CGM-22X2.5-5H |

| M24X3 | CGM-24X3-4H | CGM-24X3-5H |

| M27X3 | CGM-27X3-4H | CGM-27X3-5H |

| Metric Fine | ||

| M8X1 | CGM-8X1-4H | CGM-8X1-5H |

| M10X1 | CGM-10X1-4H | CGM-10X1-5H |

| M10X1.25 | CGM-10X1.25-4H | CGM-10X1.25-5H |

| M12X1.25 | CGM-12X1.25-4H | CGM-12X1.25-5H |

| M12X1.5 | CGM-12X1.5-4H | CGM-12X1.5-5H |

| M14X1.5 | CGM-14X1.5-4H | CGM-14X1.5-5H |

| M16X1.5 | CGM-16X1.5-4H | CGM-16X1.5-5H |

| M18X1.5 | CGM-18X1.5-4H | CGM-18X1.5-5H |

| M20X1.5 | CGM-20X1.5-4H | CGM-20X1.5-5H |

| M22X1.5 | CGM-22X1.5-4H | CGM-22X1.5-5H |

| M18X2 | CGM-18X2-4H | CGM-18X2-5H |

| M20X2 | CGM-20X2-4H | CGM-20X2-5H |

| M22X2 | CGM-22X2-4H | CGM-22X2-5H |

| M24X2 | CGM-24X2-4H | CGM-24X2-5H |

| M27X2 | CGM-27X2-4H | CGM-27X2-5H |

| M30X2 | CGM-30X2-4H | CGM-30X2-5H |

| M39X2 | CGM-39X2-4H | CGM-39X2-5H |

| M36X3 | CGM-36X3-4H | CGM-36X3-5H |

| M39X3 | CGM-39X3-4H | CGM-39X3-5H |

Please Note:

All dimensions for unified sizes in inches | All dimensions for metric sizes in millimeter | All dimensions are are for reference only.

| Thread Size |

Pitch Diameter (in) | Length A |

|||

|---|---|---|---|---|---|

| 3B | 2B | ||||

| Go | NoGo | Go | NoGo | ||

| Unified Coarse | |||||

| 1-64 | 0.0832 | 0.0843 | 0.0832 | 0.0850 | 2.5 |

| 2-56 | 0.0976 | 0.0989 | 0.0976 | 0.0996 | 2.5 |

| 3-48 | 0.1126 | 0.114 | 0.1126 | 0.1148 | 2.5 |

| 4-40 | 0.1283 | 0.1299 | 0.1283 | 0.1308 | 2.9 |

| 5-40 | 0.1413 | 0.143 | 0.1413 | 0.1438 | 2.9 |

| 6-32 | 0.1583 | 0.1601 | 0.1583 | 0.1611 | 2.9 |

| 8-32 | 0.1843 | 0.1862 | 0.1843 | 0.1872 | 3.1 |

| 10-24 | 0.217 | 0.2192 | 0.217 | 0.2203 | 3.1 |

| 12-24 | 0.243 | 0.2453 | 0.243 | 0.2464 | 3.1 |

| 1/4-20 | 0.2825 | 0.2851 | 0.2825 | 0.2863 | 3.5 |

| 5/16-18 | 0.3486 | 0.3515 | 0.3486 | 0.3529 | 3.5 |

| 3/8-16 | 0.4156 | 0.4189 | 0.4156 | 0.4203 | 4.6 |

| 7/16-14 | 0.4839 | 0.4875 | 0.4839 | 0.489 | 4.6 |

| 1/2-13 | 0.5499 | 0.5537 | 0.5499 | 0.5554 | 4.6 |

| 9/16-12 | 0.6167 | 0.6208 | 0.6167 | 0.6225 | 5.1 |

| 5/8-11 | 0.6841 | 0.6885 | 0.6841 | 0.6903 | 5.1 |

| 3/4-10 | 0.8149 | 0.8196 | 0.8149 | 0.8216 | 5.1 |

| 7/8-9 | 0.9471 | 0.9522 | 0.9471 | 0.9543 | 5.8 |

| 1-8 | 1.0812 | 1.0868 | 1.0812 | 1.0868 | 5.8 |

| 1-1/8-7 | 1.2178 | 1.2239 | 1.2178 | 1.2262 | 5.8 |

| 1-1/4-7 | 1.3428 | 1.349 | 1.3428 | 1.3514 | 6.8 |

| 1-3/8-6 | 1.4832 | 1.49 | 1.4832 | 1.4926 | 6.8 |

| 1-1/2-6 | 1.6082 | 1.6151 | 1.6082 | 1.6177 | 6.8 |

| Unified Fine | |||||

| 0-80 | 0.0681 | 0.0690 | 0.0681 | 0.0697 | 2.9 |

| 3-56 | 0.1106 | 0.1119 | 0.1106 | 0.1126 | 2.5 |

| 4-48 | 0.1256 | 0.1271 | 0.1256 | 0.1279 | 2.9 |

| 6-40 | 0.1543 | 0.1560 | 0.1543 | 0.1569 | 2.9 |

| 8-36 | 0.1821 | 0.1840 | 0.1821 | 0.1849 | 3.1 |

| 10-32 | 0.2103 | 0.2123 | 0.2103 | 0.2133 | 3.1 |

| 1/4-28 | 0.2732 | 0.2754 | 0.2732 | 0.2765 | 4.0 |

| 5/16-24 | 0.3395 | 0.3421 | 0.3395 | 0.3433 | 4.0 |

| 3/8-24 | 0.4020 | 0.4047 | 0.4020 | 0.4059 | 4.6 |

| 7/16-20 | 0.4700 | 0.4731 | 0.4700 | 0.4744 | 4.6 |

| 1/2-20 | 0.5325 | 0.5357 | 0.5325 | 0.5371 | 4.6 |

| 9/16-18 | 0.5986 | 0.6020 | 0.5986 | 0.6035 | 5.1 |

| 5/8-18 | 0.6611 | 0.6646 | 0.6611 | 0.6661 | 5.1 |

| 3/4-16 | 0.7906 | 0.7945 | 0.7906 | 0.7961 | 5.1 |

| 7/8-14 | 0.9214 | 0.9257 | 0.9214 | 0.9274 | 5.8 |

| 1-12 | 1.0542 | 1.0589 | 1.0542 | 1.0608 | 5.8 |

| 1-1/8-12 | 1.1792 | 1.1841 | 1.1792 | 1.1860 | 5.8 |

| 1-1/4-12 | 1.3042 | 1.3092 | 1.3042 | 1.3112 | 6.8 |

| 1-3/8-12 | 1.4292 | 1.4343 | 1.4292 | 1.4364 | 6.8 |

| 1-1/2-12 | 1.5542 | 1.5595 | 1.5542 | 1.5615 | 6.8 |

| Thread Size |

Pitch Diameter (mm) | Length A |

|||

|---|---|---|---|---|---|

| 4H | 5H | ||||

| Go | NoGo | Go | NoGo | ||

| Metric Coarse | |||||

| M2X0.4 | 2.260 | 2.295 | 2.260 | 2.310 | 63.5 |

| M2.2X0.45 | 2.492 | 2.532 | 2.492 | 2.547 | 63.5 |

| M2.5X0.45 | 2.792 | 2.832 | 2.792 | 2.847 | 63.5 |

| M3X0.5 | 3.325 | 3.367 | 3.325 | 3.384 | 73.6 |

| M3.5X0.6 | 3.890 | 3.940 | 3.890 | 3.959 | 73.6 |

| M4X0.7 | 4.455 | 4.509 | 4.455 | 4.529 | 78.7 |

| M5X0.8 | 5.520 | 5.577 | 5.520 | 5.597 | 78.7 |

| M6X1 | 6.650 | 6.719 | 6.650 | 6.742 | 101.6 |

| M7X1 | 7.650 | 7.719 | 7.650 | 7.742 | 101.6 |

| M8X1.25 | 8.812 | 8.886 | 8.812 | 8.911 | 101.6 |

| M10X1.5 | 10.974 | 11.061 | 10.974 | 11.089 | 116.8 |

| M12X1.75 | 13.137 | 13.236 | 13.137 | 13.271 | 116.8 |

| M14X2 | 15.299 | 15.406 | 15.299 | 15.444 | 129.5 |

| M16X2 | 17.299 | 17.406 | 17.299 | 17.444 | 129.5 |

| M18X2.5 | 19.624 | 19.738 | 19.624 | 19.778 | 129.5 |

| M20X2.5 | 21.624 | 21.738 | 21.624 | 21.778 | 129.5 |

| M22X2.5 | 23.624 | 23.738 | 23.624 | 23.778 | 129.5 |

| M24X3 | 25.948 | 26.093 | 25.948 | 26.135 | 147.3 |

| M27X3 | 28.948 | 29.093 | 28.948 | 29.135 | 147.3 |

| Metric Fine | |||||

| M8X1 | 8.650 | 8.719 | 8.650 | 8.742 | 101.6 |

| M10X1 | 10.650 | 10.719 | 10.650 | 10.742 | 116.8 |

| M10X1.25 | 10.812 | 10.886 | 10.812 | 10.911 | 116.8 |

| M12X1.25 | 12.812 | 12.898 | 12.812 | 12.926 | 116.8 |

| M12X1.5 | 12.974 | 13.067 | 12.974 | 13.099 | 116.8 |

| M14X1.5 | 14.974 | 15.067 | 14.974 | 15.099 | 129.5 |

| M16X1.5 | 16.974 | 17.067 | 16.974 | 17.099 | 129.5 |

| M18X1.5 | 18.974 | 19.067 | 18.974 | 19.099 | 129.5 |

| M20X1.5 | 20.974 | 21.067 | 20.974 | 21.099 | 129.5 |

| M22.15 | 22.974 | 23.067 | 22.974 | 23.099 | 129.5 |

| M18X2 | 19.299 | 19.406 | 19.299 | 19.444 | 129.5 |

| M20X2 | 21.299 | 21.406 | 21.299 | 21.444 | 129.5 |

| M22X2 | 23.299 | 23.406 | 23.299 | 23.444 | 129.5 |

| M24X2 | 25.299 | 25.414 | 25.299 | 25.454 | 147.3 |

| M27X2 | 28.299 | 28.414 | 28.299 | 28.455 | 147.3 |

| M30X2 | 31.299 | 31.414 | 31.299 | 31.454 | 147.3 |

| M39X2 | 40.299 | 40.414 | 40.299 | 40.454 | 171.5 |

| M36X3 | 37.948 | 38.093 | 37.948 | 38.135 | 171.5 |

| M39X3 | 40.948 | 41.093 | 40.948 | 41.135 | 171.5 |

| KATO Part Number |

Helicoil Part Number |

KATO Part Number |

Helicoil Part Number |

KATO Part Number |

Helicoil Part Number |

KATO Part Number |

Helicoil Part Number |

|---|---|---|---|---|---|---|---|

| 3B Working | 2B Working | 3B Reference | 2B Reference | ||||

| Unified Coarse | |||||||

| CGC-02X-3B | 3688-02 | CGC-02X-2B | 1442-02 | CGC-02W-3B | 1688-02 | CGC-02W-2B | 1440-02 |

| CGC-03X-3B | 3688-03 | CGC-03X-2B | 1442-03 | CGC-03W-3B | 1688-03 | CGC-03W-2B | 1440-03 |

| CGC-04X-3B | 3688-04 | CGC-04X-2B | 1442-04 | CGC-04W-3B | 1688-04 | CGC-04W-2B | 1440-04 |

| CGC-05X-3B | 3688-05 | CGC-05X-2B | 1442-05 | CGC-05W-3B | 1688-05 | CGC-05W-2B | 1440-05 |

| CGC-06X-3B | 3688-06 | CGC-06X-2B | 1442-06 | CGC-06W-3B | 1688-06 | CGC-06W-2B | 1440-06 |

| CGC-2X-3B | 3688-2 | CGC-2X-2B | 1442-2 | CGC-2W-3B | 1688-2 | CGC-2W-2B | 1440-2 |

| CGC-3X-3B | 3688-3 | CGC-3X-2B | 1442-3 | CGC-3W-3B | 1688-3 | CGC-3W-2B | 1440-3 |

| CGC-1X-3B | 3688-1 | CGC-1X-2B | 1442-1 | CGC-1W-3B | 1688-1 | CGC-1W-2B | 1440-1 |

| CGC-4X-3B | 3688-4 | CGC-4X-2B | 1442-4 | CGC-4W-3B | 1688-4 | CGC-4W-2B | 1440-4 |

| CGC-5X-3B | 3688-5 | CGC-5X-2B | 1442-5 | CGC-5W-3B | 1688-5 | CGC-5W-2B | 1440-5 |

| CGC-6X-3B | 3688-6 | CGC-6X-2B | 1442-6 | CGC-6W-3B | 1688-6 | CGC-6W-2B | 1440-6 |

| CGC-7X-3B | 3688-7 | CGC-7X-2B | 1442-7 | CGC-7W-3B | 1688-7 | CGC-7W-2B | 1440-7 |

| CGC-8X-3B | 3688-8 | CGC-8X-2B | 1442-8 | CGC-8W-3B | 1688-8 | CGC-8W-2B | 1440-8 |

| CGC-9X-3B | 3688-9 | CGC-9X-2B | 1442-9 | CGC-9W-3B | 1688-9 | CGC-9W-2B | 1440-9 |

| CGC-10X-3B | 3688-10 | CGC-10X-2B | 1442-10 | CGC-10W-3B | 1688-10 | CGC-10W-2B | 1440-10 |

| CGC-12X-3B | 3688-12 | CGC-12X-2B | 1442-12 | CGC-12W-3B | 1688-12 | CGC-12W-2B | 1440-12 |

| CGC-14X-3B | 3688-14 | CGC-14X-2B | 1442-14 | CGC-14W-3B | 1688-14 | CGC-14W-2B | 1440-14 |

| CGC-16X-3B | 3688-16 | CGC-16X-2B | 1442-16 | CGC-16W-3B | 1688-16 | CGC-16W-2B | 1440-16 |

| CGC-18X-3B | 3688-18 | CGC-18X-2B | 1442-18 | CGC-18W-3B | 1688-18 | CGC-18W-2B | 1440-18 |

| CGC-20X-3B | 3688-20 | CGC-20X-2B | 1442-20 | CGC-20W-3B | 1688-20 | CGC-20W-2B | 1440-20 |

| CGC-22X-3B | 3688-22 | CGC-22X-2B | 1442-22 | CGC-22W-3B | 1688-22 | CGC-22W-2B | 1440-22 |

| CGC-24X-3B | 3688-24 | CGC-24X-2B | 1442-24 | CGC-24W-3B | 1688-24 | CGC-24W-2B | 1440-24 |

| Unified Fine | |||||||

| CGF-03X-3B | 3694-03 | CGF-03X-2B | 1443-03 | CGF-03W-3B | 1694-03 | CGF-03W-2B | 1441-03 |

| CGF-04X-3B | 3694-04 | CGF-04X-2B | 1443-04 | CGF-04W-3B | 1694-04 | CGF-04W-2B | 1441-04 |

| CGF-06X-3B | 3694-06 | CGF-06X-2B | 1443-06 | CGF-06W-3B | 1694-06 | CGF-06W-2B | 1441-06 |

| CGF-2X-3B | 3694-2 | CGF-2X-2B | 1443-2 | CGF-2W-3B | 1694-2 | CGF-2W-2B | 1441-2 |

| CGF-3X-3B | 3694-3 | CGF-3X-2B | 1443-3 | CGF-3W-3B | 1694-3 | CGF-3W-2B | 1441-3 |

| CGF-4X-3B | 3694-4 | CGF-4X-2B | 1443-4 | CGF-4W-3B | 1694-4 | CGF-4W-2B | 1441-4 |

| CGF-5X-3B | 3694-5 | CGF-5X-2B | 1443-5 | CGF-5W-3B | 1694-5 | CGF-5W-2B | 1441-5 |

| CGF-6X-3B | 3694-6 | CGF-6X-2B | 1443-6 | CGF-6W-3B | 1694-6 | CGF-6W-2B | 1441-6 |

| CGF-7X-3B | 3694-7 | CGF-7X-2B | 1443-7 | CGF-7W-3B | 1694-7 | CGF-7W-2B | 1441-7 |

| CGF-8X-3B | 3694-8 | CGF-8X-2B | 1443-8 | CGF-8W-3B | 1694-8 | CGF-8W-2B | 1441-8 |

| CGF-9X-3B | 3694-9 | CGF-9X-2B | 1443-9 | CGF-9W-3B | 1694-9 | CGF-9W-2B | 1441-9 |

| CGF-10X-3B | 3694-10 | CGF-10X-2B | 1443-10 | CGF-10W-3B | 1694-10 | CGF-10W-2B | 1441-10 |

| CGF-12X-3B | 3694-12 | CGF-12X-2B | 1443-12 | CGF-12W-3B | 1694-12 | CGF-12W-2B | 1441-12 |

| CGF-14X-3B | 3694-14 | CGF-14X-2B | 1443-14 | CGF-14W-3B | 1694-14 | CGF-14W-2B | 1441-14 |

| CGF-16X-3B | 3694-16 | CGF-16X-2B | 1443-16 | CGF-16W-3B | 1694-16 | CGF-16W-2B | 1441-16 |

| CGF-18X-3B | 3694-18 | CGF-18X-2B | 1443-18 | CGF-18W-3B | 1694-18 | CGF-18W-2B | 1441-18 |

| CGF-20X-3B | 3694-20 | CGF-20X-2B | 1443-20 | CGF-20W-3B | 1694-20 | CGF-20W-2B | 1441-20 |

| CGF-22X-3B | 3694-22 | CGF-22X-2B | 1443-22 | CGF-22W-3B | 1694-22 | CGF-22W-2B | 1441-22 |

| CGF-24X-3B | 3694-24 | CGF-24X-2B | 1443-24 | CGF-24W-3B | 1694-24 | CGF-24W-2B | 1441-24 |

| KATO Part Number |

Helicoil Part Number |

KATO Part Number |

Helicoil Part Number |

|---|---|---|---|

| 4H Working | 5H Working | ||

| Metric Coarse | |||

| CGM-2X.4-4H | 4624-2 | CGM-2X.4-5H | 1324-2 |

| CGM-2.2X.45-4H | 4624-2.2 | CGM-2.2X.45-5H | 1324-2.2 |

| CGM-2.5X.45-4H | 4624-2.5 | CGM-2.5X.45-5H | 1324-2.5 |

| CGM-3X.5-4H | 4624-3 | CGM-3X.5-5H | 1324-3 |

| CGM-3.5X.6-4H | 4624-3.5 | CGM-3.5X.6-5H | 1324-3.5 |

| CGM-4X.7-4H | 4624-4 | CGM-4X.7-5H | 1324-4 |

| CGM-5X.8-4H | 4624-5 | CGM-5X.8-5H | 1324-5 |

| CGM-6X1-4H | 4624-6 | CGM-6X1-5H | 1324-6 |

| CGM-7X1-4H | 4624-7 | CGM-7X1-5H | 1324-7 |

| CGM-8X1.25-4H | 4624-8 | CGM-8X1.25-5H | 1324-8 |

| CGM-10X1.5-4H | 4624-10 | CGM-10X1.5-5H | 1324-10 |

| CGM-12X1.75-4H | 4624-12 | CGM-12X1.75-5H | 1324-12 |

| CGM-14X2-4H | 4624-14 | CGM-14X2-5H | 1324-14 |

| CGM-16X2-4H | 4624-16 | CGM-16X2-5H | 1324-16 |

| CGM-18X2.5-4H | 4624-18 | CGM-18X2.5-5H | 1324-18 |

| CGM-20X2.5-4H | 4624-20 | CGM-20X2.5-5H | 1324-20 |

| CGM-22X2.5-4H | 4624-22 | CGM-22X2.5-5H | 1324-22 |

| CGM-24X3-4H | 4624-24 | CGM-24X3-5H | 1324-24 |

| Metric Fine | |||

| CGM-8X1-4H | 5416-8 | CGM-8X1-5H | 4916-8 |

| CGM-10X1-4H | 5416-10 | CGM-10X1-5H | 4916-10 |

| CGM-10X1.25-4H | 5424-10 | CGM-10X1.25-5H | 4924-10 |

| CGM-12X1.25-4H | 5424-12 | CGM-12X1.25-5H | 4924-12 |

| CGM-12X1.5-4H | 5480-12 | CGM-12X1.5-5H | 4980-12 |

| CGM-14X1.5-4H | 5480-14 | CGM-14X1.5-5H | 4980-14 |

| CGM-16X1.5-4H | 5480-16 | CGM-16X1.5-5H | 4980-16 |

| CGM-18X1.5-4H | 5480-18 | CGM-18X1.5-5H | 4980-18 |

| CGM-20X1.5-4H | 5480-20 | CGM-20X1.5-5H | 4980-20 |

| CGM-22X1.5-4H | 5480-22 | CGM-22X1.5-5H | 4980-22 |

| CGM-18X2-4H | 5418-18 | CGM-18X2-5H | 4918-18 |

| CGM-20X2-4H | 5418-20 | CGM-20X2-5H | 4918-20 |

| CGM-22X2-4H | 5418-22 | CGM-22X2-5H | 4918-22 |

| CGM-24X2-4H | 5418-24 | CGM-24X2-5H | 4918-24 |