KATO Tangless® & Tanged CoilThread® Inserts

High Quality. Reliability. Flexibility. It's That Simple.

High Quality. Reliability. Flexibility. It's That Simple.

KATO Tangless and tanged CoilThread inserts are helically-coiled fastening devices that provide permanent, wear-resistant threads, exceeding the strength of most parent materials. CoilThread inserts are made of cold-rolled 304 stainless steel wire (AS7245), work-hardened to a tensile strength above 200,000 psi, and a hardness of Rc 43-50. The finished surface (32 microinches) is exceedingly smooth, virtually eliminating friction-induced thread erosion.

Tangless and tanged CoilThread inserts are available in Unified Coarse (UNC), Unified Fine (UNF), and Metric thread sizes. CoilThread inserts can be manufactured using 304 Stainless Steel as well as Nitronic 60®, Nimonic 90®, Phosphor Bronze, and more.

Tangless and tanged CoilThread inserts provide design and manufacturing flexibility.

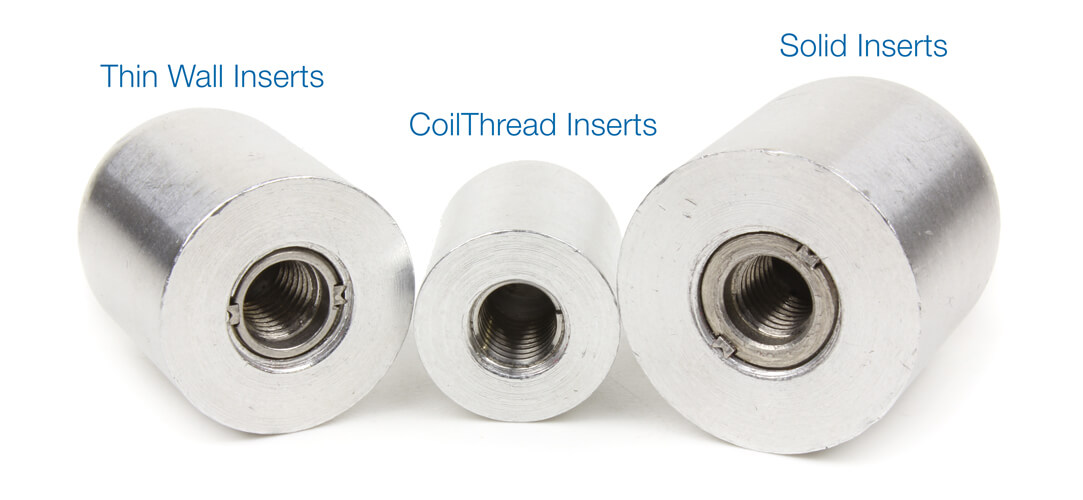

KATO CoilThread inserts are based on a continuous helically-coiled open pitch design using a diamond shaped wire. The diamond-shaped wire design allows the inserts to engage the threads in the parent material and at the same time accept a male fastener. Thus, they do not need a thick wall structure to support the internal and external threads. For the same nominal thread size, the parent material thickness requirement is less when compared with thin wall or solid inserts.

The resilient design characteristics of Coilthread inserts allow each coil to adjust independently for maximum surface contact with the parent material. As a result, loads are distributed more evenly. Stress and fatigue concentrations are reduced to maximize thread strength, thus, increasing the reliability and life of the fastening system.

CoilThread inserts are designed to be installed in reduced-sized bosses or flanges, thus saving space and weight while providing high strength. A boss radius equal to the nominal bolt diameter is usually sufficient.

Precision engineering, exacting manufacturing standards, and stringent quality control procedures are utilized during entire manufacturing process to assure a high quality product that meets or exceeds all applicable military and aerospace requirements. KATO CoilThread inserts have been put through rigorous torque, tension, and vibration tests as well as comprehensive dimensional inspections and metallurgical analysis in attaining their MIL-SPEC qualifications. CoilThread inserts have been thoroughly tested by an independent testing laboratory and are certified to conform to NASM8846.

When installed into STI tapped holes (per NASM33537 for unified and MA1567 for metric), CoilThread inserts provide a finish thread meeting the requirement of FED-STD-H28. Assembled CoilThread insert will also accommodated UNJ (MIL-S-7742 and AS8879) male threaded fasteners. For additional information on applicable military and aerospace standards please refer to the MA/MS/NAS Specs.

The image above depicts weight and space savings provided by utilizing CoilThread inserts. All three samples have the same internal thread, and as you can see CoilThread inserts require the smallest boss diameter.

KATO Tangless CoilThread inserts are identical, in form, fit, and function to the conventional tanged inserts (CoilThread, Helicoil, Recoil). In fact, Tangless CoilThread inserts are identical to tanged inserts in every way except for their method of installation and removal, and they have the exact same procurement specification (NASM8846 for unified sizes and MA1565 for metric sizes).

KATO Tangless and tanged CoilThread inserts are used extensively in aircraft applications, such as engines, gear boxes, fuel systems, radar, avionics, flight controls, lighting and HVAC systems. They are also used widely by the military and in many other electronic, mechanical, and commercial applications. The KATO Tangless, FOD-free design is the preferred standard for optimum thread assemblies in new fastening system designs.

Emerging technologies have created new insert requirements, triggering the development of innovative insert materials to meet those exacting needs such as higher temperature capabilities, reduced friction, corrosion resistance, increased strength and other requirements.

The following insert materials are specifically engineered to meet the demanding requirements of our customers’ applications:

This is the most popular insert material, and it will satisfy most application requirements for strength, corrosion resistance and temperature capability. The inserts can be used in applications with a temperature range from -320° F to 800° F. Cold rolling the stainless steel wire to a diamond shape work-hardens it to a tensile strength above 200,000 PSI, a hardness of Rc 43-50 and a smooth 32 micro-inch finish. The inserts become slightly magnetic from the work-hardening that occurs during the manufacturing process (approx. 2-10 G/O). The insert material is covered by specifications AS7245, NASM8846 and alloy number UNS S30400.

Inserts are supplied in this material for higher temperature capability and reliability applications. Inconel X-750 inserts have approximately the same strength and hardness characteristics of 304 stainless steel inserts, but can be used in environments up to 1,000° F. The material is a nickel-chromium alloy, made precipitation hardenable by the additions of aluminum and titanium. It has good rupture resistance at higher temperatures, good corrosion and oxidation resistance and a lower magnetic permeability than 304 stainless steel inserts (< 1.0 G/O). Typical applications include gas turbines, rocket engines, nuclear reactors, pressure vessels, and various aircraft components operating in higher temperature environments. The insert material is covered by specification AS7246.

For part numbers see Cross Reference.

Inserts made from this material are ideal for salt water applications and have superior corrosion resistance over 304 Stainless Steel and Inconel X-750, although it is not as strong as either material. It has a tensile strength of approximately 140,000 PSI and a hardness of HRB 95. Phosphor Bronze inserts are also used in applications requiring very low magnetic permeability (< 1.0 G/O), low electrical connectivity and conductivity, and they can be used in environments up to 572℉. Typical applications Include Naval vessels, aircraft instrumentation paper and textile manufacturing, automotive systems, mining and drilling equipment, pumps and valves, and electrical connectors. The insert material is covered by specification AMS7247.

For part numbers see Cross Reference.

Inserts made from Nitronic 60 are specifically engineered to eliminate galling and fretting when used with stainless steel screws. The surface friction between the mating screw and the Nitronic 60 insert is superior to 304 Stainless Steel inserts due to the additions of silicon and manganese to the alloy which reduces wear and galling, thus particulate matter is eliminated completely or minimized. The inserts require no additional coatings or platings, making them ideal for use in a vacuum as there is no out gassing, and they are not limited by the lower temperature capabilities of some platings and coatings, e.g. cadmium and dry film lubricant. The inserts are non-magnetic (< 1.0 G/O), have good corrosion resistance, a tensile strength of approximately 200,000 PSI, a hardness of Rc 43-50 and can be used in temperatures up to 500° F. Typical applications include semiconductor, aerospace industries, or when requirements indicate the use of 300 series Stainless Steel male fasteners. The material is metal alloy number UNS S21800.

For part numbers see Cross Reference.

For Reference Only

Inserts made from Nimonic 90 are used in high temperature environments where pressure and heat are extreme. It is a nickel-chromium-cobalt alloy that is precipitation hardenable and having high stress-rupture strength at elevated temperatures. Nimonic 90 is an ideal material for applications in aircraft parts and gas turbine components, such as jet engine exhaust nozzles. Typically free running inserts are used in environments with temperatures up to 1200° F and locking inserts up to 900° F. The chemical composition of Nimonic 90 is Ni 54%, Cr 18-21%, Co 15-21%, Ti 2-3%, and Al 1-2%. The material is covered by British Standard BS HR 503.

For Reference Only

Inserts made from Titanium have a superior strength to weight ratio over 304 Stainless Steel inserts. They also provide very good corrosion resistance and are non-magnetic. Titanium inserts are slightly lower in tensile strength (150,000 to 220,000 PSI) and hardness (Rc 35-43), but are approximately 45% lighter in weight than 304 Stainless Steel inserts, making them ideal where weight reduction is critical. Titanium is very stable and its low coefficient of thermal expansion makes it an excellent choice for use in aerospace applications, such as satellites that must survive temperature fluctuations from sub-zero to 600° F (maximum temperature for insert applications). Titanium is used in biomedical applications; as it is compatible with the human body it is used extensively for applications that involve biological implants. Titanium inserts are covered by material specifications AMS 4957 and AMS 4958A.

Please Note:

KATO Tangless and tanged CoilThread inserts are used in a wide range of Aerospace and Commercial applications. Although CoilThread inserts are manufactured from Stainless Steel, many applications require additional protection from galling and/or corrosion. KATO offers CoilThread inserts with the following: Platings and Coatings.

The most versatile, and most popular, coating applied to KATO Tangless and tanged CoilThread inserts is the Dry Film Lubricant. The Dry Film Lubricant is applied to limit galling between the insert and the fastener. The Dry Film Lubricant is a Molybdenum Disulfide applied in accordance with AS5272 (Type 1). On Locking or Free-Running inserts, the coating will be Dark Gray to Black in color (NASM8846).

In addition, Molybdenum Disulfide has inherent corrosive inhibiting qualities: Galvanic Corrosion Resistance – Independent testing indicates Molybdenum Disulfide may be suitable for certain applications requiring resistance from galvanic corrosion.

The suffix “W” is added to KATO part numbers (ex. 2TLC-02C-0086W) to signify the application of Dry Film Lubricant.

For part numbers see Cross Reference.

Cadmium plating KATO Tangless and tanged CoilThread inserts significantly increases corrosion protection. Cadmium plating is primarily used to protect against corrosion, but like Molybdenum Disulfide, helps decrease the coefficient of friction between the insert and the bolt to minimize galling.

Cadmium is applied in accordance with AMS-QQ-P-416. The identification colors vary depending on the type of inserts (locking vs. free-running). A supplemental Olive Drab to Dark Brown chromate is required to identify Locking Inserts. Gold to Yellow chromate is required to identify Free-Running Inserts (NASM8846).

Cadmium plating is meant to show no evidence of corrosion when exposed to a continuous salt spray test (96 hour ASTM B 117 test in accordance with NASM1312-1).

The suffix “Y” is added to KATO part numbers (ex. 2TLC-02C-0086Y) to signify the application of Cadmium.

For part numbers see Cross Reference.

Xylan plating is a "chrome-free" fluropolymer coating applied to KATO Tangless and tanged CoilThread inserts to help prevent corrosion. Xylan is a waterborne/VOC compliant, resin bonded, thermally cured, single dry film lubricant, and known as an "extreme performance coating".

The suffix “P” is added to KATO part numbers (ex. 2TLC-02C-0086P) to signify the application of Xylan.

Silver plating is applied in accordance with customer requested AMS specifications. Commonly, AMS2410 is used for low to mid-range temperatures, or AMS2411 is used for high temperatures up to 1400°F. For additional specifications please contact the KATO Support. Cloudy White is the standard color.

The suffix “V” is added to KATO part numbers (ex. 2TLC-02C-0086V) to signify the application of Silver.

Electroless Nickel plating on KATO Tangless and tanged CoilThread inserts provides wear resistance and corrosion protection. Electroless Nickel is applied in accordance with AMS-C-26074, unless otherwise specified by the customer. Polished Silver is the standard finish.

The suffix “E” is added to KATO part numbers (ex. 2TLC-02C-0086E) to signify the application of Electroless Nickel.

Although passivation is not actually a plating/coating, this supplemental treatment is sometimes required by the application. KATO passivates inserts in accordance with AMS2700.

KATO does not make it standard practice to passivate active stainless steel CoilThread inserts. This minimizes the possibility of galvanic corrosion occurring when they are installed in aluminum or magnesium parent materials.

The suffix “A” is added to KATO part numbers (ex. 2TLC-02C-0086A) to signify the passivation requirement.

Color Identifier Green – Add a “G” suffix to KATO part numbers (ex. 2TLC-02C-0086G) to signify green dye. The green dye is standard printers ink and may be removed with a cleaning solution.

Color Identifier Blue – Add a “B” suffix to KATO part numbers (ex. 2TLC-02C-0086B) to signify blue dye. The blue dye is standard printers ink and may be removed with a cleaning solution.

Please Note:

Tangless and tanged CoilThread inserts are available in bulk form, typically 1000 pcs/bag, larger thread sizes (above 1/2" and M12) may be packaged in smaller quantities. Thread sizes up to 5/16" and M8 are available on plastic strip-feed reels, typically 1000 pcs/reel. KATO strip-feed packaged inserts are ideal for use with the KATO Prewinder Electric and Prewinder Air tools.

Smaller quantities of bulk inserts are available through our network of master distributors. Please contact one of our authorized distributors to get the best service, support, and pricing on KATO Tangless and tanged CoilThread inserts.

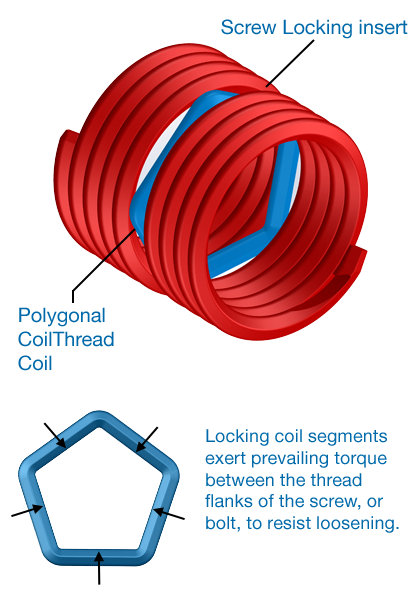

KATO screw locking inserts exert a prevailing torque on male threaded fasteners to prevent loosening due to vibration or impact. Locking inserts eliminate the need for costly and less desirable locking mechanisms. They are excellent in adjusting screw applications by preventing the male fastener from creeping.

One of the biggest misconceptions regarding locking type says helically-coiled screw thread inserts is that the insert has a feature which locks it into place in the parent material. This is not the case. Locking inserts apply a locking, or prevailing, torque on the male fastener.

Locking inserts contain one or more coils that have a series of straight segments. Upon entry of the bolt these straight segments are flexed outwardly, creating pressure on the bolt. This pressure is applied between the flanks of the bolt thread so that contact area is maximized.

CoilThread screw locking inserts are manufactured to meet the locking torque requirement specified in NASM8846 (Unified) or MA1565 (Metric). Both requires the inserts to pass a 15 cycle torque test; it is often possible to realize a cycle life far in excess of specification requirements.

For additional information on locking inserts and prevailing torque, please read these articles in KATOpedia:

Locking inserts conform to NAS1130 (unified Tangless), NA0276 (metric Tangless), NASM21209 (unified tanged), MA3329 (metric tanged), and produce locking torques in accordance with NASM8846 (unified) and MA1565 (metric) when used with heat treated cadmium-plated bolts. When using unplated heat treated or stainless steel bolts, an anti-seize compound, e.g. molybdenum disulfide, must be used in order to minimize galling and assure maximum cycle life. Wear life of the male fastener can also be improved by specifying dry film lubricant or cadmium plating. The use of 300 series stainless steel bolts should be avoided when using locking inserts. Use A286 aircraft quality screws or equivalent (Rc 36-43).

| Thread Size |

Maximum Locking Torque |

Minimum Breakaway Torque |

||

|---|---|---|---|---|

| Unified Coarse | ||||

| 1-64 | 15.0 | oz-in | 2.0 | oz-in |

| 2-56 | 20.0 | oz-in | 3.0 | oz-in |

| 3-48 | 32.0 | oz-in | 7.0 | oz-in |

| 4-40 | 48.0 | oz-in | 10.0 | oz-in |

| 5-40 | 75.2 | oz-in | 13.0 | oz-in |

| 6-32 | 6.0 | lbf-in | 1.0 | lbf-in |

| 8-32 | 9.0 | lbf-in | 1.5 | lbf-in |

| 10-24 | 13.0 | lbf-in | 2.0 | lbf-in |

| 12-241 | 24.0 | lbf-in | 3.0 | lbf-in |

| 1/4-20 | 30.0 | lbf-in | 4.5 | lbf-in |

| 5/16-18 | 60.0 | lbf-in | 7.5 | lbf-in |

| 3/8-16 | 80.0 | lbf-in | 12.0 | lbf-in |

| 7/16-14 | 100.0 | lbf-in | 16.5 | lbf-in |

| 1/2-13 | 150.0 | lbf-in | 24.0 | lbf-in |

| 9/16-12 | 200.0 | lbf-in | 30.0 | lbf-in |

| 5/8-11 | 300.0 | lbf-in | 40.0 | lbf-in |

| 3/4-10 | 400.0 | lbf-in | 60.0 | lbf-in |

| 7/8-9 | 600.0 | lbf-in | 82.0 | lbf-in |

| 1-8 | 800.0 | lbf-in | 110.0 | lbf-in |

| 1-1/8-7 | 900.0 | lbf-in | 137.0 | lbf-in |

| 1-1/4-7 | 1000.0 | lbf-in | 165.0 | lbf-in |

| 1-3/8-6 | 1150.0 | lbf-in | 185.0 | lbf-in |

| 1-1/2-6 | 1350.0 | lbf-in | 210.0 | lbf-in |

| Unified Fine | ||||

| 3-56 | 32.0 | oz-in | 7.0 | oz-in |

| 4-48 | 48.0 | oz-in | 10.0 | oz-in |

| 6-40 | 6.0 | lbf-in | 1.0 | lbf-in |

| 8-36 | 9.0 | lbf-in | 1.5 | lbf-in |

| 10-32 | 13.0 | lbf-in | 2.0 | lbf-in |

| 1/4-28 | 30.0 | lbf-in | 3.5 | lbf-in |

| 5/16-24 | 60.0 | lbf-in | 6.5 | lbf-in |

| 3/8-24 | 80.0 | lbf-in | 9.5 | lbf-in |

| 7/16-20 | 100.0 | lbf-in | 14.0 | lbf-in |

| 1/2-20 | 150.0 | lbf-in | 18.0 | lbf-in |

| 9/16-18 | 200.0 | lbf-in | 24.0 | lbf-in |

| 5/8-18 | 300.0 | lbf-in | 32.0 | lbf-in |

| 3/4-16 | 400.0 | lbf-in | 50.0 | lbf-in |

| 7/8-14 | 600.0 | lbf-in | 70.0 | lbf-in |

| 1-12 | 800.0 | lbf-in | 90.0 | lbf-in |

| 1-1/8-12 | 900.0 | lbf-in | 117.0 | lbf-in |

| 1-1/4-12 | 1000.0 | lbf-in | 143.0 | lbf-in |

| 1-3/8-12 | 1150.0 | lbf-in | 165.0 | lbf-in |

| 1-1/2-12 | 1350.0 | lbf-in | 190.0 | lbf-in |

| Thread Size |

Maximum Locking Torque |

Minimum Breakaway Torque |

||

|---|---|---|---|---|

| Metric Coarse | ||||

| M2X0.4 | 0.12 | N.m | 0.003 | N.m |

| M2.2X0.45 | 0.14 | N.m | 0.02 | N.m |

| M2.5X0.45 | 0.23 | N.m | 0.06 | N.m |

| M3X0.5 | 0.45 | N.m | 0.10 | N.m |

| M3.5X0.6 | 0.68 | N.m | 0.12 | N.m |

| M4X0.7 | 0.90 | N.m | 0.16 | N.m |

| M5X0.8 | 1.60 | N.m | 0.30 | N.m |

| M6X1 | 3.00 | N.m | 0.40 | N.m |

| M7X1 | 4.50 | N.m | 0.60 | N.m |

| M8X1.25 | 6.00 | N.m | 0.80 | N.m |

| M10X1.5 | 10.50 | N.m | 1.40 | N.m |

| M12X1.75 | 15.50 | N.m | 2.20 | N.m |

| M14X2 | 23.50 | N.m | 3.00 | N.m |

| M16X2 | 31.50 | N.m | 4.20 | N.m |

| M18X2.5 | 42.00 | N.m | 5.50 | N.m |

| M20X2.5 | 54.00 | N.m | 7.00 | N.m |

| M22X2.5 | 67.50 | N.m | 9.00 | N.m |

| M24X3 | 80.00 | N.m | 11.00 | N.m |

| M27X3 | 94.00 | N.m | 12.00 | N.m |

| Metric Fine | ||||

| M8X1 | 6.00 | N.m | 0.80 | N.m |

| M10X1 | 10.50 | N.m | 1.40 | N.m |

| M10X1.25 | 10.50 | N.m | 1.40 | N.m |

| M12X1.25 | 15.50 | N.m | 2.20 | N.m |

| M12X1.5 | 15.50 | N.m | 2.20 | N.m |

| M14X1.5 | 23.50 | N.m | 3.00 | N.m |

| M16X1.5 | 31.50 | N.m | 4.20 | N.m |

| M18X1.5 | 42.00 | N.m | 5.50 | N.m |

| M20X1.5 | 54.00 | N.m | 7.00 | N.m |

| M22X1.5 | 67.50 | N.m | 9.00 | N.m |

| M18X2 | 42.00 | N.m | 5.50 | N.m |

| M20X2 | 54.00 | N.m | 7.00 | N.m |

| M22X2 | 67.50 | N.m | 9.00 | N.m |

| M24X2 | 80.00 | N.m | 11.00 | N.m |

| M27X2 | 94.00 | N.m | 12.00 | N.m |

| M30X2 | 108.00 | N.m | 14.00 | N.m |

| M33X2 | 125.00 | N.m | 16.00 | N.m |

| M39X2 | 150.00 | N.m | 20.00 | N.m |

| M36X3 | 136.00 | N.m | 18.00 | N.m |

| M39X3 | 150.00 | N.m | 20.00 | N.m |

Please Note:

| To Convert From | To | Multiply by |

|---|---|---|

| N.m | ozf-in | 141.6119 |

| N.m | lbf-in | 8.850748 |

| ozf-in | N.m | 0.0070615 |

| lbf-in | N.m | 0.1129848 |