Torque Basics

Torque by definition is the moment of a force, a measure of its tendency to produce torsion and rotation about an axis, equal to the vector product of the radius vector from the axis of rotation to the point of application of the force by the force applied. Easy enough … right?

Let’s simplify this a bit to a broad definition of a turning or twisting force. Our Torsional Analysis Department at KFS is inundated with all sorts of inquiries on torque, so much so that it has prompted us to write an article on this exciting subject. As we are limited to two columns of space by our editor, we will confine our discussion to how torque applies to CoilThread® Inserts.

Torque is normally expressed in the English system as oz-in, lb-in, or lb-ft, and in the metric system as N-m (Newton-meter). An easy way to visualize torque would be if you had a wrench that was 2 feet long, and you were tightening a bolt. If you applied 3 lbs. of force to the end of the wrench you would be tightening the bolt to 3 lbs. × 2 feet, or 6 lb-ft of torque. (Not bad huh? I thought this up myself.)

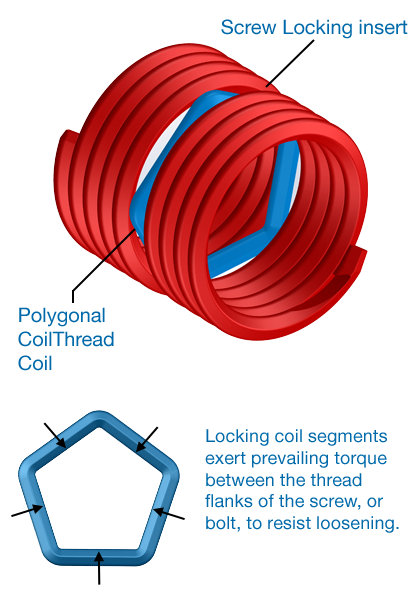

Now let’s talk about inserts. Locking type inserts have a series of chords, or straight segments on one or more coils usually located in the middle of the insert. The locking feature applies pressure to the bolt or screw, thus putting a prevailing torque on the screw to prevent or minimize the possibility of the screw loosening and backing out of the insert.

The locking feature does NOT lock the insert into the tapped hole, nor does it prevent the bolt from loosening after the bolt is in the clamped (tightened down) condition. Whew, this is getting heavy.

This brings us to another subject – How tight do you make the bolt or screw? The tightening torque of the bolt is usually driven by the bolt material. For example, you could not tighten a plastic bolt to the same torque as a hardened steel bolt. There are many other factors for determining the optimum tightening torque for a particular application, but we will limit this discussion to length of engagement and shear strength of the parent material.

If a customer asks us what the bolt tightening torque should be when used with an insert, the easy answer is the torque is the same as it would be without an insert. However, if a locking insert is used, there is a loss of some the bolt tightening torque due to the friction from the locking element. Therefore, the bolted assembly would not be as tight using a locking insert vs. a free-running insert with the same tightening torque applied to the bolt. To get the optimum tightening torque for an application using a locking insert, the actual torque of the bolt going through the insert locking element would have to be measured, and then this value added to the recommended tightening torque for the bolt.

Did you know that when you tighten down a bolt, the majority of the tightening torque is lost due to friction? Yes, that’s right, about 85 to 90%! Check this out:

| Percent of Tightening Torque | ||

|---|---|---|

| UNC* | UNF** | |

| Bolt Tension | 15% | 10% |

| Thread Friction | 39% | 42% |

| Head Friction | 46% | 48% |

| Total Torque | 100% | 100% |

*Unified National Coarse Threads

**Unified National Fine Threads

If you have any questions, please contact us.

For more technical articles, register to KATOpedia today! Registration is FREE, and take less than 1 minute to complete and gain access to the world's most comprehensive online encyclopedia for helically coiled screw thread inserts and tools.