Locking Torque - Differences in Actual vs. Published Values

The KATO Tech Group often receives inquiries from customers asking us why the locking torque they are measuring in their particular application differs from that published in the National Aerospace Standard that specifies the torque limits for helical coil inserts, and also from those values found in the KATO catalog. NASM8846 specifies the torque limits for both tanged and Tangless® Inserts and these same values can be found in our catalog and on our website.

The reasons for the varying results are relatively simple, but there are several contributory factors. The test criteria called out in NASM8846 is very specific, and varying from the particulars of this specification will invariably result in measured torque values that differ from the published values.

Parent Material

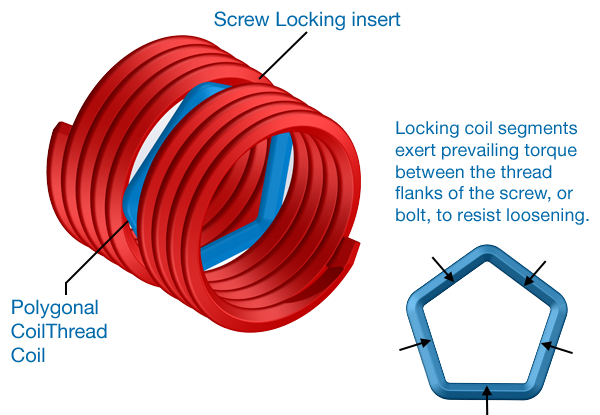

NASM8846 specifies that the Test Nuts, or Test Plates for the torque tests be made of 2024-T4 or T351 Aluminum. If your application uses a material that is either softer or harder than these aluminum materials, the locking torque could be affected by the amount of outward expansion of the locking coils. For example, in a very soft parent material, the locking coil would expand outward further into this material possibly resulting in lower measured insert locking torques.

Tapped Hole Class of Fit and Minor Diameter

We will limit this discussion to holes tapped with thread cutting taps, as the reasons thread forming taps are not recommended are covered in Article 0902,Thread Forming Taps for STI Tapped Holes. NASM8846 specifies the tapped holes and inserts in the test pieces be in accordance with NASM33537. Variations in the tapped hole thread tolerances will affect the insert locking torque. An oversized tapped hole will invariably result in lower locking torques and an undersized tapped hole will usually result in higher locking torques. The minor diameter also plays a roll in drilled hole size determines the percentage of full thread. The corner of the locking coils cannot expand outward as easily if the minor diameter is undersized which can result in higher locking torques.

Bolt Material and Hardness

We saved this one for last, as this is the most common reason for differences in measured vs. published torque values. NASM8846 specifies that the test bolts be MS16997, etc. or that equivalent Class 3A cadmium plated socket head cap screws may be substituted for the NAS and MS bolts. The bolts used in this test are typically in the hardness range of 38-42 Rc, which is very close to the insert hardness, 43-50 Rc.

In addition the cadmium plating on the bolts provides lubricity to prevent galling of the test bolts with the locking coils during the tests. We receive many calls where customers are using unplated, 300 series stainless steel bolts with locking inserts and their results typically vary above or below the published torque values. The primary reason for this is that this bolt material is too soft to be used with locking inserts, and there is no plating or lubricant to minimize galling and seizing. Dry film lubricant coating on the inserts will help this situation, but will not always solve it.

Other factors that will affect locking torque results are the use of locking and sealing compounds in the tapped holes (not recommended), use of zinc chromate or epoxy primers, and supplementary treatments to the tapped holes that affect the thread class of fit, such as anodize, irridite, chem film, chromate, etc.

In conclusion, we will note that every manufactured lot of KATO tanged and Tangless inserts are torque tested per NASM8846 and this are certified in the Certificate of Compliance. The actual torque test results by part number and lot number are on file at KATO Fastening Systems and are included the Chemical & Physical Reports.

Related Topics in previous issues of KATO Fastening News:

- Galling Protection

- Torque Basic

- Locking Inserts - Do's, Don'ts, and FAQ

- Thread Forming Taps for STI Tapped Holes

If you have any questions, please contact us.

For more technical articles, register to KATOpedia today! Registration is FREE, and take less than 1 minute to complete and gain access to the world's most comprehensive online encyclopedia for helically coiled screw thread inserts and tools.